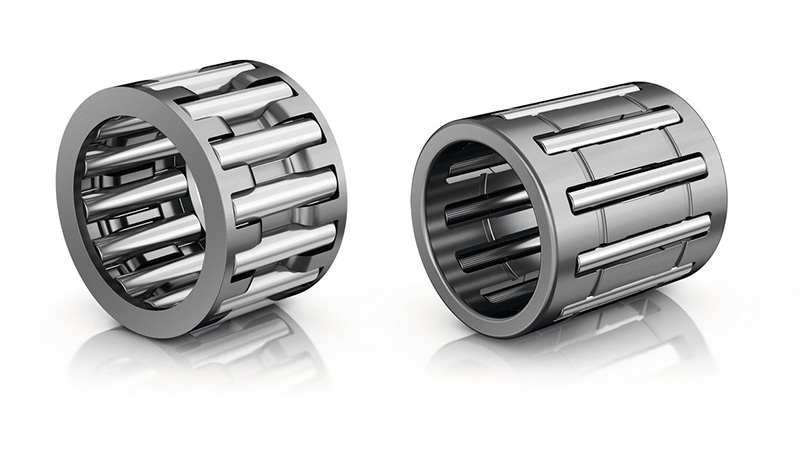

Needle Roller and Cage Assemblies

Apart from full complement needle roller sets, the needle roller and cage assembly is the simplest design of needle roller bearing. Needle roller and cage assemblies are of single or double row design and comprise a cage and needle rollers. Since their radial section height corresponds directly to the diameter of the needle rollers, needle roller and cage assemblies allow bearing arrangements with the very smallest radial design envelope. If the raceways are produced to high geometrical accuracy, high radial run-out accuracy can be achieved.

Since they do not have an outer ring or inner ring, they run directly on the shaft and in the housing. The shaft and the housing bore must be designed as a rolling bearing raceway. The radial internal clearance is influenced by the shaft and housing tolerances as well as the grade of the needle rollers. Needle roller and cage assemblies must be located axially by means of snap rings or an appropriate design of the adjacent construction with abutment shoulders.

Radial needle roller and cage assemblies can support high radial loads and allow high speeds. They combine the load carrying capacity advantages of full complement needle roller bearing arrangements with the speed advantages of a cage bearing and are easy to mount.